Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

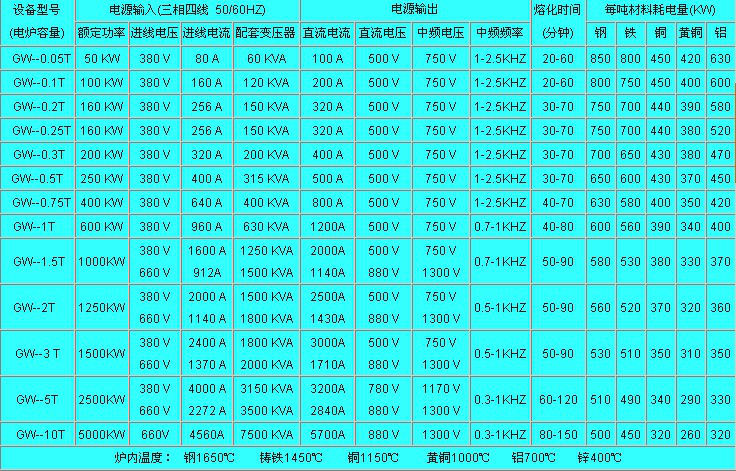

Main frequency and technical parameters of intermediate frequency melting furnace

The intermediate frequency melting furnace is a frequency conversion device that converts the three-phase power frequency current into a single-phase intermediate frequency current, and causes the metal to generate eddy current loss by electromagnetic field induction, thereby achieving the purpose of heat generation and melting. Used for smelting, heating, heat preservation and forging, sintering, hot rolling, and through-tube heat treatment of black or non-ferrous metals and alloy materials such as steel, copper, aluminum, zinc, tin, nickel, gold and silver. Mainly used in the foundry melting industry.

Medium frequency melting furnace performance characteristics

1. It adopts zero voltage scanning soft start mode, which can be started or stopped at any time under any state, and has no impact on the power supply.

2. Rapid smelting and low production cost; low pollution and environmental protection requirements.

3. It can be directly melted from the cold furnace, and the solution can be completely emptied. It is convenient to replace the melt.

4. The power adjustment is flexible, convenient, and can be continuously and smoothly adjusted; the temperature is uniform and easy to control, the oxidation loss is small, and the metal composition is uniform.

5. The furnace shell adopts cast aluminum alloy or steel shell structure, and the floor space is small; the furnace body is easy to turn over and tilt, and electric, manual, hydraulic and other tilting furnace methods can be selected according to needs.

6. The automatic adjustment circuit of the inverter angle is designed, which can automatically adjust the matching of the load impedance. The device can be operated in a good working state without adjusting the compensation capacity. The power supply system has the function of diagnosis error and is easy to overhaul.

Main model and technical parameters

Parameter Description

1. Melting time and ton of electricity consumption are related to factors such as equipment power, material shape, material weight, and worker proficiency.

2. One power supply for the equipment; two sets of furnace body; one capacitor cabinet; two reducers; two water cooling cables.

3. The above is the standard product data, and can design different powers and non-standard products with different melting speeds according to user needs.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur