Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

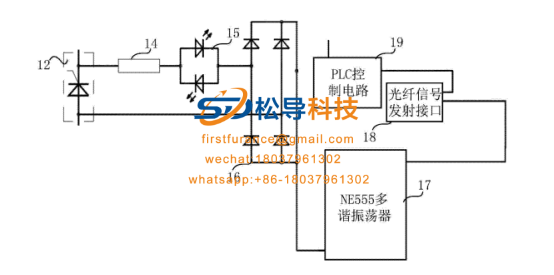

The utility model provides a coreless induction melting furnace and a monitoring circuit. The monitoring circuit includes a rectifier circuit, a signal processing circuit for converting a voltage signal into a switch control signal, a signal transmitting interface and a PLC control circuit. The rectifier circuit is electrically connected to a thyristor voltage output terminal, the rectifier circuit is electrically connected to the signal processing circuit, and the switching control signal output by the signal processing circuit is transmitted to the PLC control circuit through a signal transmission interface. The PLC control circuit is electrically connected to a switch circuit and is configured to receive a switch control signal. The switch circuit is provided in a power supply circuit of the induction melting furnace and is configured to form a loop when the power supply circuit is closed. The coreless induction melting furnace includes a plurality of thyristors and a plurality of the above-mentioned monitoring circuits corresponding to the thyristors on a one-to-one basis. The application can directly display the operation of the thyristor, quickly and effectively detect the failure of the thyristor, and stop the machine in time to protect the personal safety of the equipment and the operator.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur