Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

How does the PC rebar heat treatment production line work?

PC steel bar is the abbreviation of prestressed concrete steel bar. The surface of the steel bar is threaded and can adhere well to the concrete. The heat treatment of PC steel bars includes intermediate frequency preheating, high frequency final heating, quenching, and intermediate frequency tempering. Its heat treatment production line includes press conveyor, heating induction coil, quenching chamber, tempering induction coil, straightening machine, cutting machine and so on.

Due to the large production volume of the PC steel rebar processing production line, the quality of this production line is evaluated. In addition to product quality, energy consumption indicators are an important aspect. Luoyang Songdao Induction Heating Technology Co., Ltd. recommended a set of induction hardening and tempering systems for the treatment of prestressed concrete steel bars for building structures, bridge piers, and concrete pillars. This system can also be used to manufacture other concave rebars, steel wires, and round steel bars. The entire system replaces direct resistance heating for the final heating. The system is designed to process steel bars with a diameter of 6-12mm and feed at a moving speed of 35m/min.

The system uses an intermediate frequency power supply for preheating, a solid-state high frequency power supply for the final heating before quenching, and another intermediate frequency power supply for tempering. The heating temperature before quenching is 940~950, and the tempering temperature is 400. The system is also equipped with rebar feed vent protection, power control corresponding to the feed speed, circulating cooling water pump station and quenching cooling medium circulation system. The only control cabinet interlocks all the main operating functions.

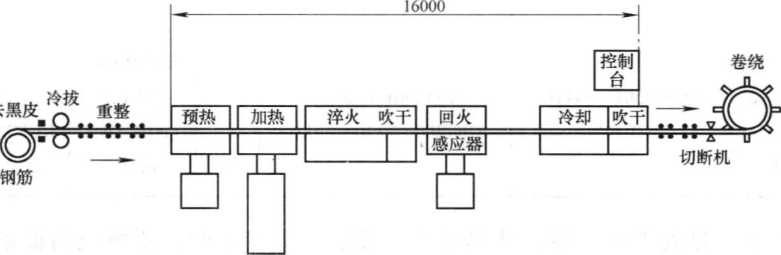

The production process of induction hardening and tempering of PC steel bars is shown in Figure 8-43: the steel bar is blackened, cold drawn, reformed, preheated (below the Curie point), heated (above the Curie point), quenched, and dried. Tempering heating-cooling-drying-roll bale. There is a cutting machine in front of the bundle drum, which will be activated when the bundle is full.

Figure 8-43 Schematic diagram of the induction hardening and tempering production process of PC steel bars

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur