Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

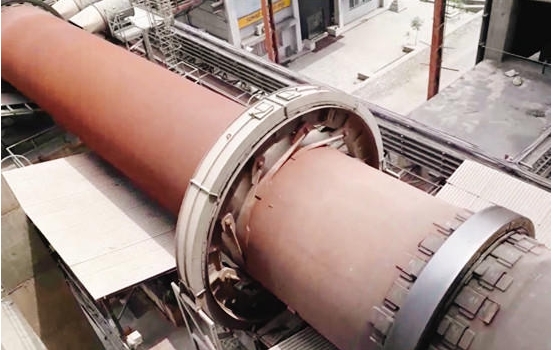

Influencing factors of wear and tear of refractory lining of cement rotary kiln

As the main equipment for calcination of cement clinker in cement plants, the rotary kiln can also be used in the lime industry. It has the characteristics of large output, uniform product calcination, and stable production. Commonly used refractory materials mainly include high alumina bricks, phosphate bonded high alumina bricks, anti-stripping high alumina bricks, mullite alkali-resistant composite bricks, silica-molded bricks, magnesia refractory bricks, steel fiber reinforced refractory castables, and low cement castables , Anti-skinning castable, etc.

Rotary kiln equipment can be divided into front kiln mouth, lower transition zone, firing zone, upper transition zone, decomposition zone and rear kiln mouth. According to the operating environment and temperature of each part, in the production operation of the rotary kiln, The refractory lining of its lining will be affected by the turning movement of the cylinder and the material, the influence of the combustion flue gas of the coal injection pipe and the high temperature charge, and the erosion of harmful gases, etc., and also include the kiln masonry design, refractory quality, masonry Building quality, oven requirements, etc., will shorten the service life of the lining refractories.

In order to ensure the long-term and continuous safe operation of the rotary kiln, the refractory lining of the rotary kiln should be as stable and as long as possible, but there are many factors that affect the service life of the rotary kiln. The refractory lining of the kiln is mainly subjected to three aspects: mechanical stress, thermal stress and chemical erosion. The role of.

1. The influence of mechanical stress on the refractory material of the rotary kiln lining:

In the normal production process of the rotary kiln, the relative movement of the cylinder, materials, dust-laden furnace gas, etc. and the inner lining itself causes the refractory to be subjected to gravity load and abrasion. When the mechanical stress load exceeds the strength limit that the refractory can withstand At this time, it will cause rapid damage to the refractory material.

The main mechanical stress generating factors are as follows:

(1) The cylinder is deformed. The total weight of the refractory materials, materials and the barrel body in the kiln exceeds the strength of the barrel body or the local burning temperature is too high. Damaged and peeled brick lining occurred.

(2) Axis offset. The tire belt, supporting roller, roller support and each broken center point on the axis of the rotary kiln should be in a straight line. Under the influence of its own gravity, the central axis will shift. After a period of operation, the tires and rollers will experience different degrees of wear and shift. The load-bearing capacity of each support point becomes uneven, which intensifies the axis. The amount of offset, the lining refractory material will be damaged or even fall off due to extrusion.

(3) Construction quality. Due to unreasonable design or masonry problems, the refractory materials are loosened during operation, causing misalignment and distortion, and during the continuous operation of the rotary kiln, the relative movement of the cylinder and the lined refractory material occurs, and the refractory materials are mutually affected. The effect causes extrusion dislocation, and even spalling or even falling off.

2. The influence of thermal stress on the refractory materials of the rotary kiln:

Thermal stress means that during the heating process of the kiln, the refractory materials are extruded due to different degrees of thermal expansion, and because they cannot expand freely, when the force exceeds the strength of the refractory material itself, the refractory material in the kiln will be damaged , Peeling and other phenomena. In addition, with the operation of the kiln, periodic fluctuations in the surface temperature of the lining refractory material will affect it; and when the kiln starts and stops, the temperature change of alternating cold and heat will also affect the lining of the kiln. The influence of temperature changes on the kiln lining inside the kiln is also one of the reasons for the damage of the kiln lining.

3. The influence of chemical attack on the refractory materials of the rotary kiln:

The chemical attack of refractory materials in rotary kiln mainly comes from the calcination of raw materials and the fuel itself. The impurities in the raw materials include SiO2, Fe2O3, Na2O, K2O, etc., and the impurities in the fuel S, P, Cl and other compounds. These impurities are immersed in high temperature environments. Inside the refractory material, a chemical reaction occurs with the refractory lining matrix, causing a series of damage to the refractory material. The chemical reaction between the liquid phase material and the surface of the refractory at high temperature, as well as the penetration and erosion of harmful substances such as alkali salt, causes the surface reaction layer of the refractory to peel and crack when it encounters the combined effect of thermal and mechanical stress.

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur