Sales hot line ( 24 hours service): 18037961302

E-Mail: firstfurnace@gmail.com

whatsapp:+8618037961302

Adress: Luoxin Industrial Park, Luoyang, HenanLarge diameter steel pipe quen

Piston rod quenching and tempe

Grinding rod quenching and tem

High frequency induction heate

Quenching equipment for machin

Round steel end heating furnac

Steel pipe heat treatment prod

Square steel quenching and tem

Sucker rod quenching and tempe

Thickened petroleum steel pipe

Round steel quenching and temp

Steel pipe quenching and tempe

Steel plate quenching and temp

Induction Hardening Machine&nb

Flywheel ring gear high freque

How does the quenching of the guide wheel induction heating furnace work?

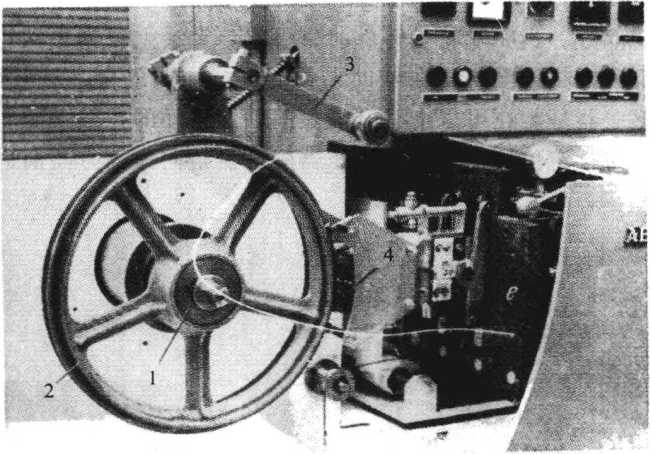

The difference between the guide wheel and drive wheel quenching machine is that the former is a scanning quenching, while the latter is a one-time heating and quenching. Figure 8-32 shows the main part of the quenching of the guide wheel induction heating furnace. The quenching of the guide wheel induction heating furnace is generally applicable to the quenching of the driving wheel induction heating furnace, but a set of rotation device is installed on the workpiece positioning shaft, which can make the positioning shaft perform stepless speed change. When the guide wheel is quenched and heated, the left and right wheel faces and shoulders are carried out at the same time, and there is a liquid sprayer under the effective circle of the sensor. When the guide wheel is scanned and quenched to the end, there must be a transition zone for repeated heating. In order to reduce the length of the transition zone, the width of the effective part of the sensor cannot be designed too wide; in order to prevent the transition zone from being generated on a straight section, when the effective circle of the sensor is arranged on two rims, it should be separated from the front and back. distance.

Figure 8-32 The main part of guide wheel induction heating furnace quenching

1 a workpiece support 2-guide wheel 3-indexing device (removed) 4 a double loop sensor

Iron induction furnace

Aluminum melting furnace

Copper melting furnace

Small steel melting furnace

Small induction melting furnace

Induction iron furnace

3T intermediate frequency iron melting f

0.25T Intermediate Frequency Furnace

0.5T Intermediate Frequency Furnace

Medium Frequency Furnace

2T Induction Melting Furnace

1T Induction Melting Furnace

500kg Induction Melting Furnace

250kg Induction Melting Furnace

Induction Melting Furnace

3 T Induction Melting Furnace

5T Induction Melting Furnace

1T One Belt Two Intermediate Frequency F

5T One Belt Two Intermediate Frequency F

3T One Belt Two Intermediate Frequency F

2T One Belt Two Intermediate Frequency F

5T Parallel Intermediate Frequency Furna

5T Intermediate Frequency Furnace

5T Series Intermediate Frequency Furnace

3T Series Intermediate Frequency Furnace

2T Series Intermediate Frequency Furnace

1T Series Intermediate Frequency Furnace

0.5T Series Intermediate Frequency Furna

0.25T Series Intermediate Frequency Furn

1T Parallel Intermediate Frequency Furna

2T Parallel Intermediate Frequency Furna

0.5T Parallel Intermediate Frequency Fur